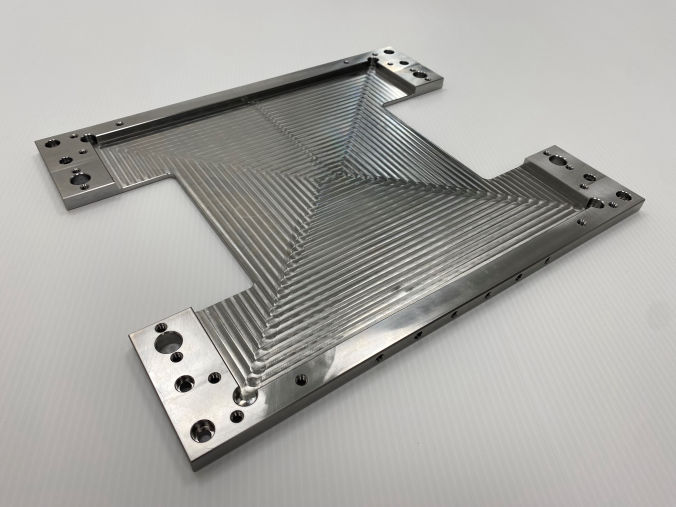

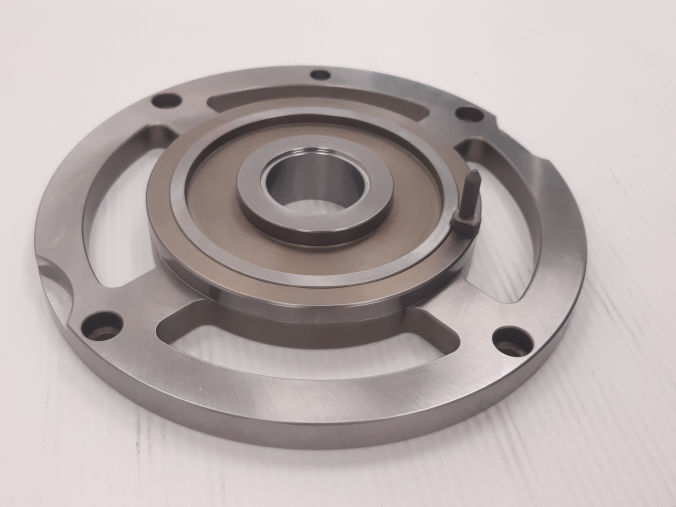

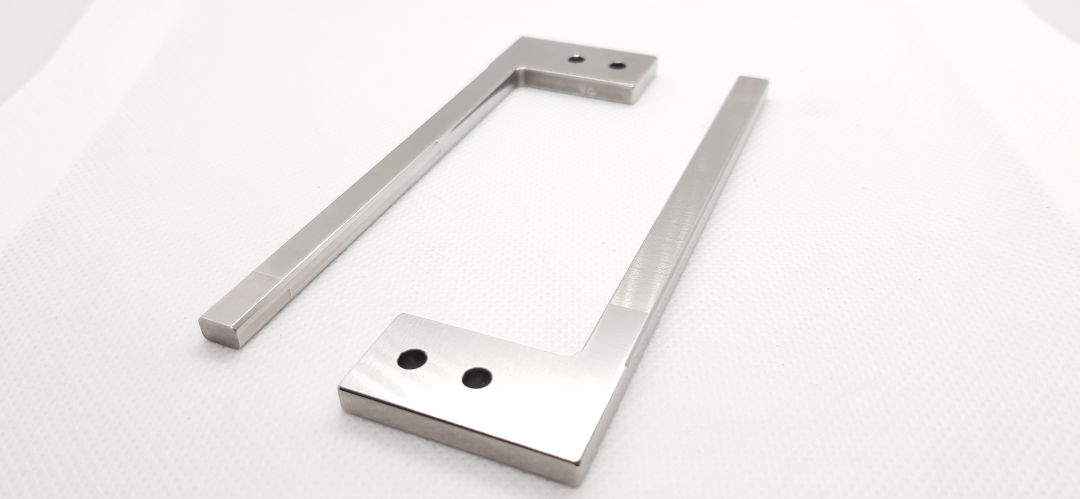

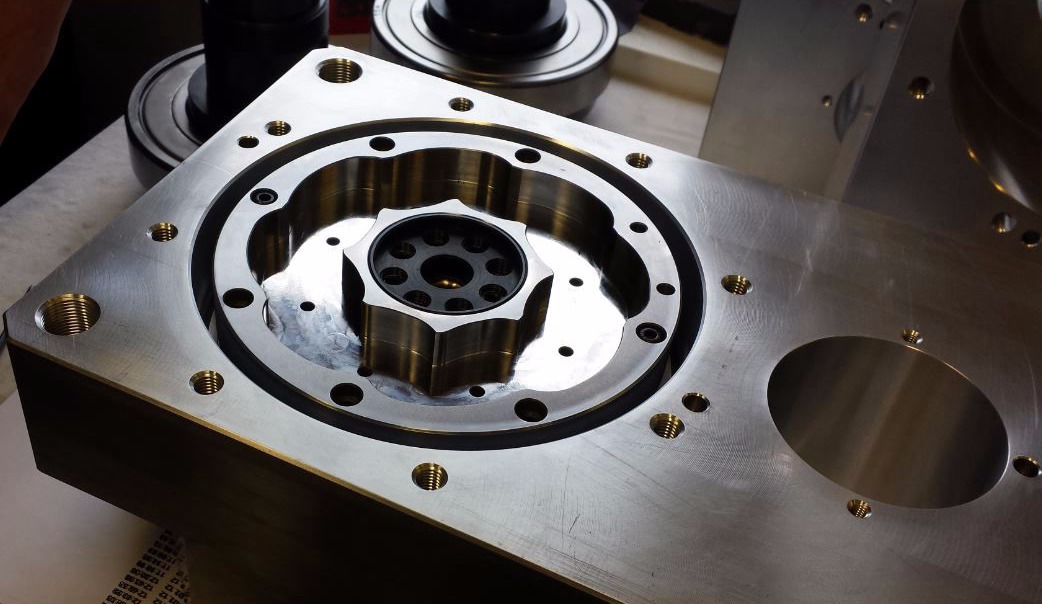

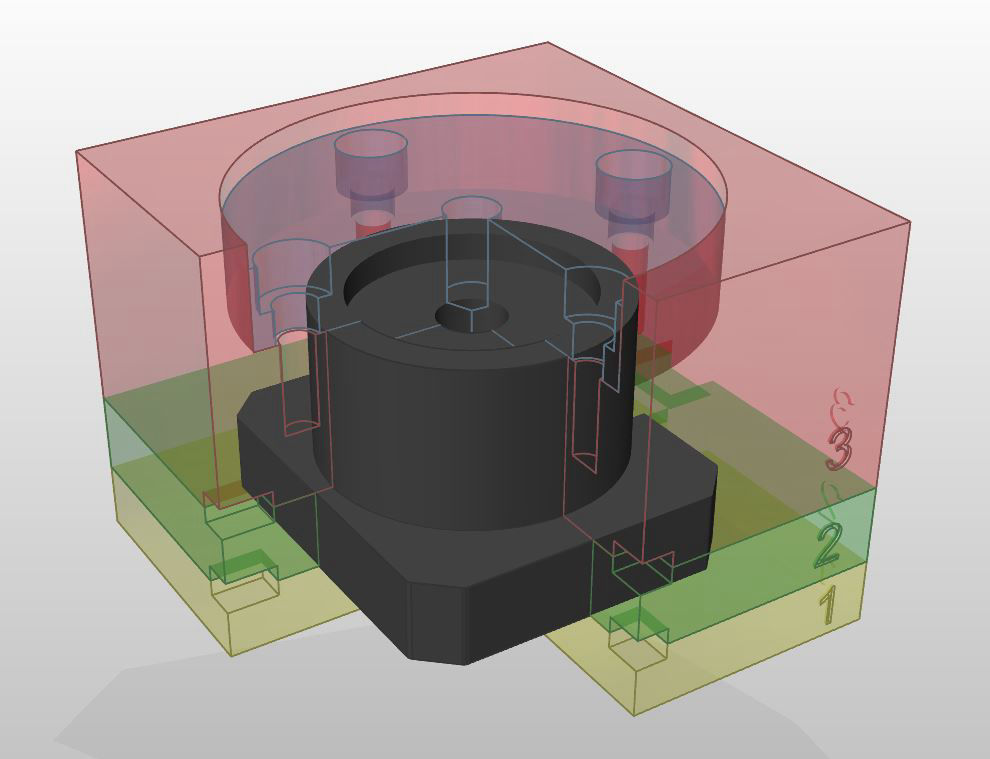

We produce 2,000-2,500 high-quality parts per year on 3- and 4-axis high-precision HURCO machining centers

We are also capable of performing more complex operations on our C and Y-axis CNC lathes with driven tools

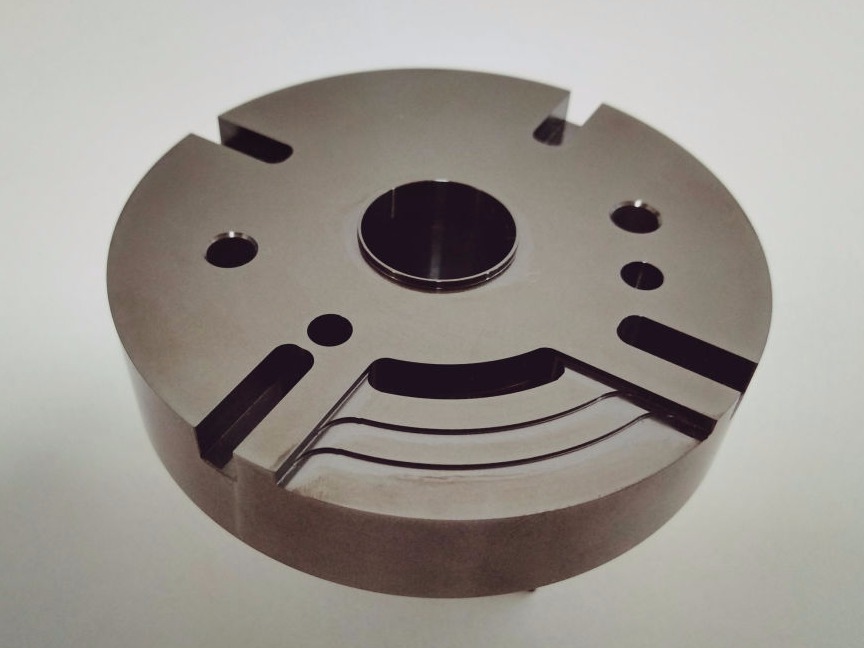

With our precision grinding machines, we can achieve excellent surface quality while achieving the desired dimensions, shape and position tolerances.

Our grinding technologies: Jacket and hole grinding; plane grinding and coordinate grinding

We can process complex shapes with a Sodick precision wire EDM machine

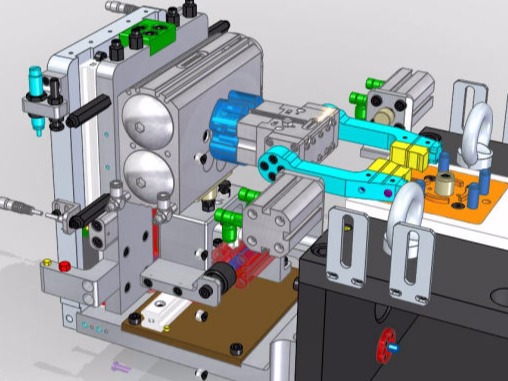

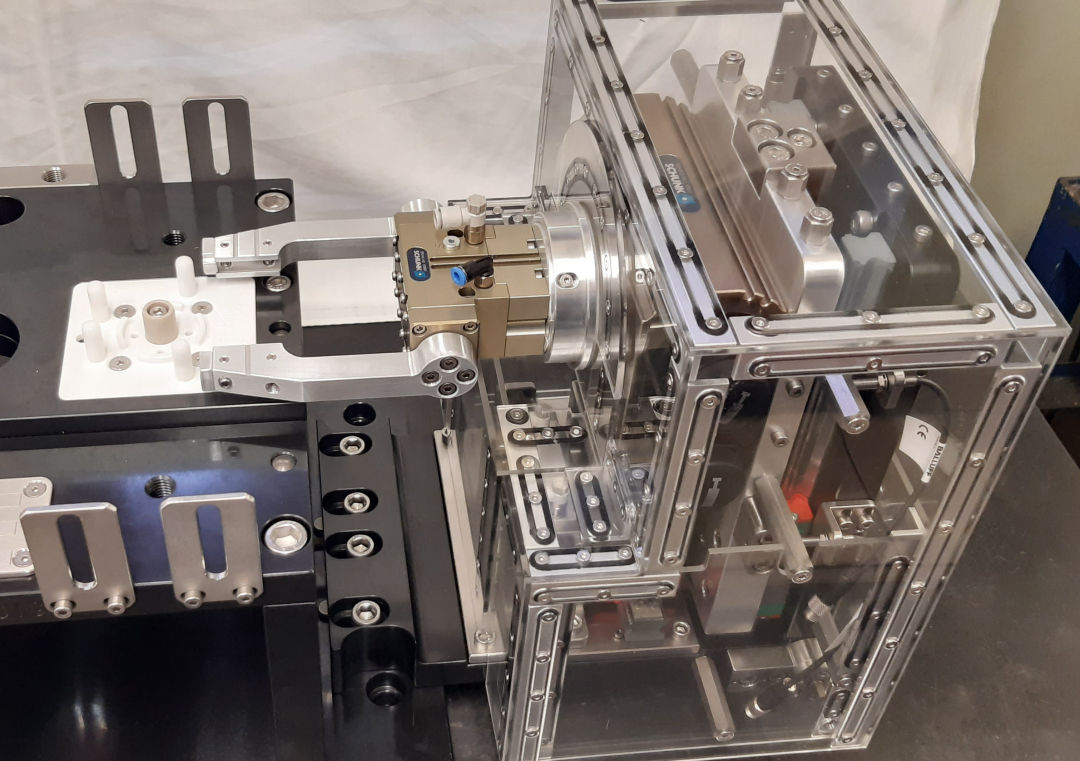

We also participate in the planning, redesign and preparation of services and projects, if the customer wishes

In our measuring laboratory, we can ensure the high quality of manufactured parts with Wenzel CNC measuring machines, together with measurement documentation if required

"I set strict professional and quality requirements for myself and my colleagues, which our customers honor with their trust."

Necessary requirements for this:

- working based on mutual respect

-conscious capacity development

-research and use of new technologies

-continuous training of our staff

- protecting our environment

-building relationships with additional partners thanks to our success and good reputation

- continuous development of our ISO 9001:2015 quality management system

- Automotive supplier with Japanese interests

- Our status: Qualified supplier

- Automotive supplier with German interest

- Our status: Qualified supplier

Zalaszentlászló, Hajnal 19.

8788 Hungary

Zalaszentlászló, Kossuth Lajos 124.

8788 Hungary

+36 30 513 0800

+36 30 639 8627

Tax number : 22910282-2-20